Value Engineering Services

Tooling

What type of tools do you produce?

By acting as both a domestic producer and international exporter of machine tooling from Asia, Cypress Industries manufactures a large variety of custom design tooling. These include custom designed tools for plastic injection molding, plastic extrusion, metal injection molding, metal die casting, aluminum extrusions, investment casting, permanent mold, sand casting, machining fixtures, deep drawn stamping, and progressive die stamping.

Tools for plastic injection molding can be made for either mass production or prototype tooling (including rapid prototype tooling). The term prototype tooling can be a misnomer because, depending on the plastic material and type of part, we can typically get anywhere from 5,000 to 100,000 parts out of an aluminum prototype tool. For more information on prototype tooling please visit our Aluminum Tooling in the U.S. page. For more detailed information on tooling, please choose from the categories on our plastics tooling page.

Mass production custom design tooling for plastic injection molding can also be manufactured in a variety of metals in both the US and China, as Cypress is an exporter of machine tooling from Asia. Typically we will use P20 tool steel for production tools unless specifically requested by the client to quote a harder metal like H13 tool steel. Our clients will normally specify up front if they desire a H13 tool able to run at least 1,000,000 parts. This realistically can only be achieved with H13 tool steel. P20 tool steel will typically run 500,000 parts. These quantities vary greatly depending on the type of material being run (how abrasive is the plastic?) to the shape of the part and the tonnage of the machine.

For high volume metal products, it is not uncommon for there to be no charge for additional custom tooling once a tool is worn out. This is normally due to the lower cost of most metal tools and tooling steel. Most of the time our clients will not realize tool rework charges when running high volumes of metal parts unless the tooling price is very high and the piece part price uncharacteristically low.

Where do you produce tools?

Cypress Industries manufactures tooling both in the United States and in China. With this extent of manufacturing capabilities, Cypress is able to manufacture custom tooling in China and export the machine tooling from Asia back into the US. This depends on the needs of our clients. Tools manufactured in China are typically much less expensive, although the lead-time to get parts to the U.S. can be longer. Clients needing custom steel tools manufactured quickly, or needing lower run prototype aluminum tooling will typically choose to have their tools manufactured in the U.S.

We have extremely large facilities for custom design tooling in China, and more moderate facilities for quick turn United States tooling.

- How does the tooling process work and what is a typical tooling timeline?

Cypress Industries follows a very standard machine tooling supply process. It is very important the tooling process be followed properly so the client receives the best possible custom designed tool for their parts. If this is not done properly, tooling problems may arise such as longer cycle times, which will lead to higher unit costs. We strive to provide our clients with the best possible tooling for their unique situation.

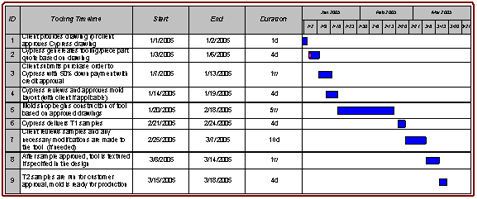

Every product’s tooling timeline varies depending on its complexity and at what stage Cypress Industries becomes involved. A typical timeline for a basic tool from receiving drawings to the final parts being approved is listed below (please click to enlarge):

The timeline provided above is an approximation for a product of average complexity. Some less complex projects may experience quicker timelines. Likewise, more complex projects may experience significantly longer timelines.

What are the typical costs for tooling?

Tooling costs can vary greatly depending on both the project and where the tool is built. Please visit our Plastics Tooling page to see a chart of estimated tooling costs for different sized products and manufacturing locations.

Will you manufacture tools for me to run elsewhere?

Yes, Cypress Industries manufactures about 30% of its custom tools for customers just needing tooling. We call this “tooling for export” when manufacturing in China. Cypress will accommodate your need to have your tool made in China and act as an exporter of your tool from Asia to the US. If you deliver us drawings, or hire us to design your part, we will manufacture tooling and package it for shipping to your location. Please make sure you tell your salesperson you are interested in tooling for export, because if we are manufacturing tools in China and export them, certain duties need to be included in the quotation.