Value Engineering Services

Industrial & Braided Wire Harnesses

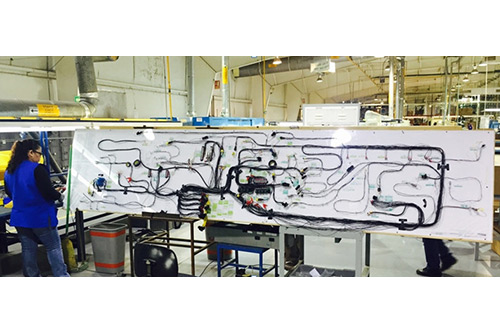

Cypress Industries designs and manufactures dependable, custom-braided wiring harnesses built to meet the exacting needs of any industry. Our wire harness braiding equipment allows us to define the right solution for your operation, addressing variables from durability and abrasion resistance to tensile strength and aesthetics.

Harsh environments demand well-crafted assemblies. An industrial wire harness may need to perform perfectly for years while being subjected to constant abrasion and vibration. Heavy duty harnesses may need to move quickly in any direction, or withstand shocks that can disengage connections. We’ll work from your drawings or work with you to fabricate a braided wire harness that includes the right mix of materials, maximizing flexibility, tensile strength, abrasion resistance and durability.

Downtime can become the most expensive part of repairs. Training can add significantly to the cost of labor. But well-designed, aesthetically-pleasing industrial wire harnesses can minimize these costs, allowing technicians to locate problems with minimal effort and enabling new workers to learn their way around your equipment in the shortest possible time. With minimum orders, we can braid wire harnesses in custom colors and lay out the entire assembly in the most logical way, creating ROI that extends far beyond the harness itself.

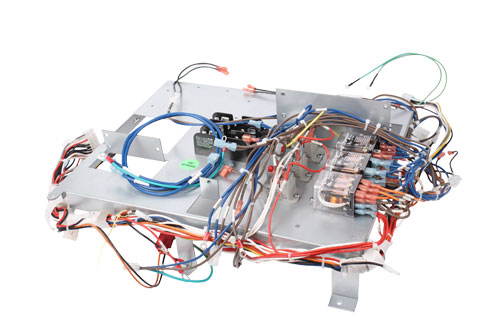

We craft rugged wire harnesses, including IP67-rated waterproof harnesses, for any kind of environment, including the extremely harsh conditions faced by the oil and gas industries, the military and other government agencies. We serve the automotive, agriculture, solar and wind energy, HVAC and other industrial markets, which demand exactly the kind of abrasion-resistant wire harnesses we specialize in. Our braiding capabilities provide the kinds of wire harness protection demanded by all kinds of equipment, including cranes, HVAC pump and fan control, pneumatic and hydraulic systems and lift stations - a significant improvement over cable tubing.

![]() We are proud to have grown into a leading provider of complex solutions in the industrial wire harness assembly arena through persistent attention to detail and quality throughout our manufacturing process. With harnesses from single conductor that would extend hundreds of feet long with hundreds of breakouts and connecters, Cypress continually delivers a product that has been fully electrically tested and meets or exceeds our customer expectations. With continuity testers, electrical testers, skilled soldering experts, IPC standards, Ohms resistance, and cross connect verification, we are able to repeatedly deliver a product that is immediately placed into its final destination without any additional testing on a part of our customers. Cypress also has multiple braiding machines, for extremely small diameter wires up to several inches of diameter, using an industry standard nylon braid that is extremely rugged and resistant and meets the caterpillar spec of braiding. We also have the capability of changing colors of this braid to meet specific demands required by our individual customers.

We are proud to have grown into a leading provider of complex solutions in the industrial wire harness assembly arena through persistent attention to detail and quality throughout our manufacturing process. With harnesses from single conductor that would extend hundreds of feet long with hundreds of breakouts and connecters, Cypress continually delivers a product that has been fully electrically tested and meets or exceeds our customer expectations. With continuity testers, electrical testers, skilled soldering experts, IPC standards, Ohms resistance, and cross connect verification, we are able to repeatedly deliver a product that is immediately placed into its final destination without any additional testing on a part of our customers. Cypress also has multiple braiding machines, for extremely small diameter wires up to several inches of diameter, using an industry standard nylon braid that is extremely rugged and resistant and meets the caterpillar spec of braiding. We also have the capability of changing colors of this braid to meet specific demands required by our individual customers.

Joey,

Production Manager